-

Phone

86-21-53082298

-

Address

Room 135, Zone a, No. 668 East Beijing Rd, Shanghai, China

-

E-mail

LatestProducts

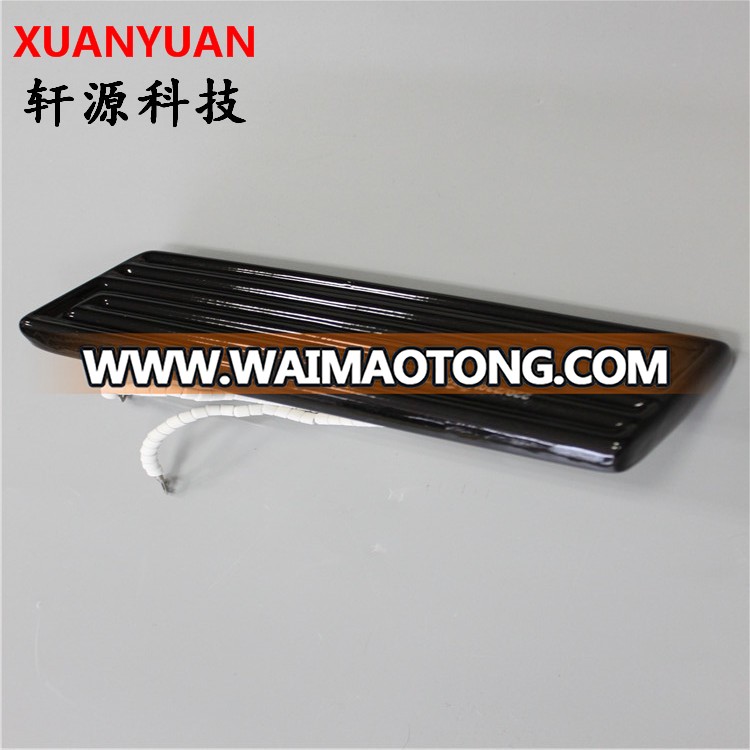

Ceramic Far Infrared IR Heater

China Ceramic Far Infrared IR Heater, Find details about China Embedding Type Ceramic Far Infrared Radi, Ceramic Rectangular Flat Emitters from Ceramic Far Infrared IR Heater - Shanghai Gongtao Ceramics Co., Ltd.

Description

Basic Info

- Model NO.: GT-006

- Housing Material: Ceramic

- Certification: RoHS

- Color: Cream,White,Black,Red

- Shape: Flat,Curve.Square,Screw

- Trademark: shangtao

- Origin: Shanghai, China

- Installation: Horizontal Type

- Usage: Bathroom, Kitchen

- Brand: Shangtao

- Power: 110W,240W,400W,650W,1000W

- Size: 245X65,240X60,120X60,120X120

- Specification: Rohs

- HS Code: 8516800000

Product Description

Embedding type ceramic far infrared radiated elements apply glaze with high radiance,ceramic with good heat and shock property as base,and are sintered once by nichrome wire.

Gongtao company can produce based on specification of customer.

Shape:black hollow core,disk,flat plate,arc

Optional Power: 100W-2000W(based on size)

Other:thermocouple,probe of thermocouple

|

1. Rupture strength for base body: |

440Kg/cm2 |

|

2.Resistance in common temperature: |

10 12 ohm 0 cm |

|

3.Property:good chemical stability;strong causticity-resistance;perfect oxidation-resistance | |

|

4.Heat losing in the non-radiation surface is small | |

|

5.The base body is heated to 800 C and put in cold water repeatly for ten times and no cracking. | |

|

6.The radiated element is heated after electrifying to rating power and immerged into cold water after interruption of power supply for forty times without damage. | |

|

7.The max radiance of element>0.9 | |

|

8.The effect of energy saving is obvious,increasing 10-25% compared with silicon carbide element | |

|

9.The life span can prolong more than a few times compared with silicon carbide element. | |

| Plastic Industries: | Thermoforming & Vacuum Forming for plastification of Sheets / rolls. Lamination and welding of Plastic. Curing / Shrinking Of PVC Paste. |

| Rubber Industries: | Preheating & vulcanizing of rubber Sheets. Preheating of Synthetic Pipes Before Coupling. |

| Textile Industries: | Drying Of finished Textile / Garments / Carpets. Setting of Nylon & Perlon Threads. |

| Paper Industries: | Drying of Paper Pulp, Drying of Paper Glue. Drying of Paper Coating, Adhesive Activation. |

| Paint Industries: | Stoving for Car Bodies epoxy. Lacquer Steel Panels. |

| Screen Printing : | Ink Drying, Instruments Dial Plastic. Fascia Panel Aluminum. |

| Food & Other Industries : | Baking & Browing Of Bakery Products, Packaging Food Product. Drying Tobacco, Sprayed and Powder Coating. |